THERMAL CLEANING

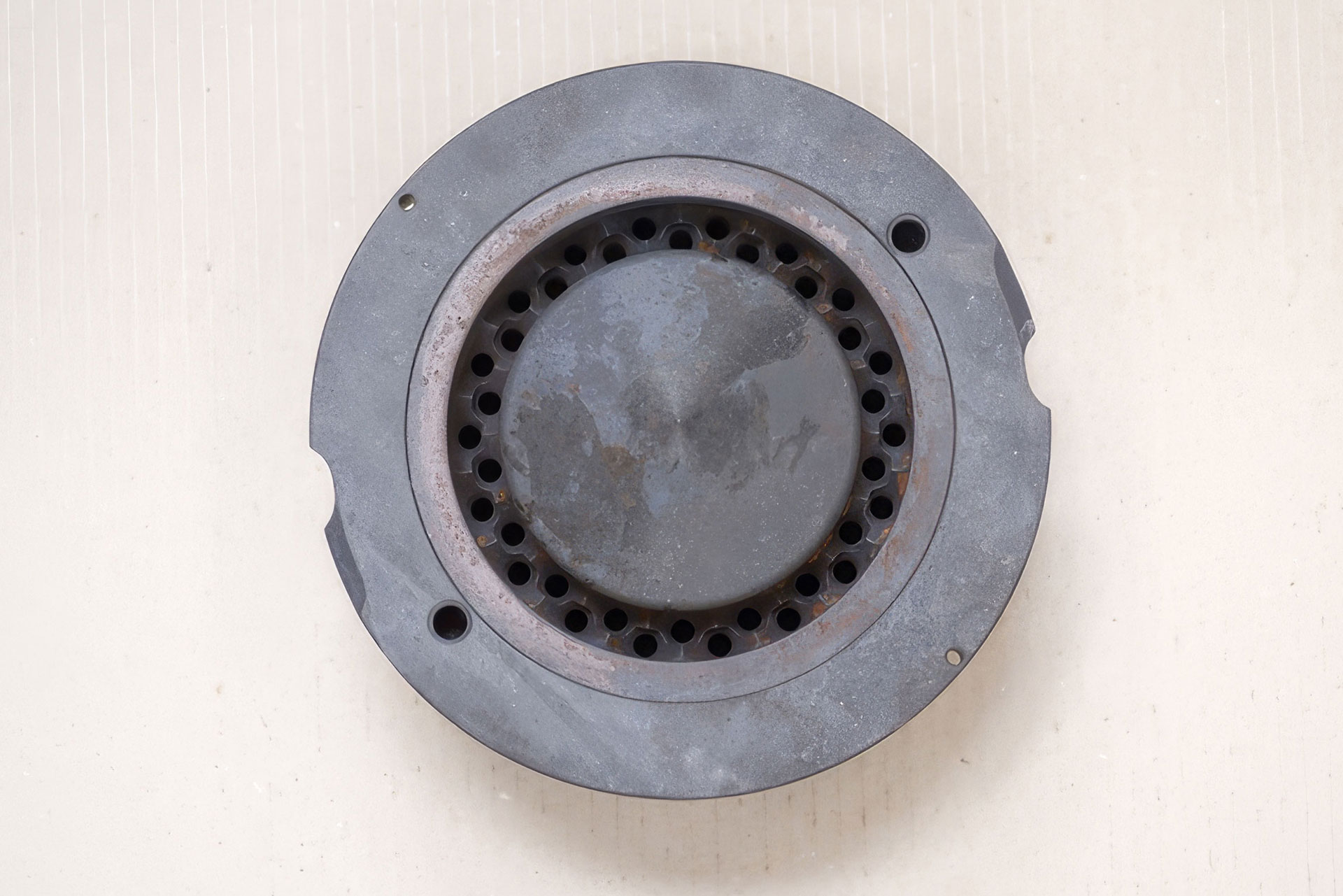

Complex tools, machine parts and components in the plastics processing industry must be cleaned and maintained regularly to ensure high production quality.

Mechanical cleaning is time-consuming and also reduces surface quality.

When tools and machine parts are removed from the production process for maintenance purposes, the adhering plastic and any plastic remaining inside cools and hardens. This is where thermal cleaning comes in, in which the plastics (polymers/organic materials) are first decomposed into gases and carbon at temperatures of approx. 430 °C and above. The carbon remaining from this pyrolysis process is then completely removed in a thermal oxidation phase. This unique, material- and tool-specific combination of targeted pyrolysis and thermal oxidation takes place in special furnace systems.

We can clean parts up to a size of 1650x1500x2400mm and a weight of 2500kg.

We would be pleased to arrange a meeting to check with you whether thermal cleaning is suitable for your application.

We look forward to your enquiry!

For further information about this service, please contact:

- Gabriel Schiefer

- +43 (0) 2674 808

- office@unistrap.com